The laboratory incubator is essential equipment for many laboratory studies. It is used to ensure an optimal environment for cell growth and to keep living and cellular organisms at controlled temperatures. For this reason, it is important that the incubator complies with the requirements and regulations required for laboratories. A common problem associated with these devices is heat leakage. If not addressed in time, heat leakage can cause damage to machinery and generally to experiments conducted in the incubator.

One of the most common problems with laboratory incubators is heat leakage, either because of the uneven opening of the door or because the ventilation has not been adequate. This can cause extreme temperatures that affect internal experiments and may damage other equipment.

Elementary Precautions

To prevent the incubator from becoming an ineffective source of heat, there are some elementary precautions that should be considered. First, ensure that the incubator is properly calibrated. This involves periodically checking the temperature reading, which conforms to pre-set parameters for experiments.

A crucial measure to prevent heat escape is the removal of all foreign objects within the incubator that may contribute to heat escape. This means making sure that there are no additional heat sources, such as direct light from a nearby window, inside the incubator. Additional cables should also be removed to prevent unnecessary heating.

As for ventilation, modern systems have sensors that detect changes in internal temperature to prevent the escape of heat through ventilation. These sensors must be adjusted appropriately to create a balance in the flow of heat in and out of the incubator.

Another way to prevent heat leakage in a laboratory incubator is to check the integrity of the pipe. This means that the insulation of the pipe, as well as its connection to other equipment within the system, must be checked periodically. This ensures that heat escape is kept to a minimum.

Calibration Techniques

It is essential that users ensure that all materials within the incubator are heat resistant. This means that any sudden temperature changes will not affect the cells or materials inside the incubator.

Ultimately, several techniques can be used to prevent heat leakage in a laboratory incubator. These techniques include proper calibration, removal of all foreign objects, adjustments to ventilation, strict control of pipe integrity, and verification of heat resistance of materials within the incubator. These techniques will allow the laboratory incubator to be kept at the correct temperature.

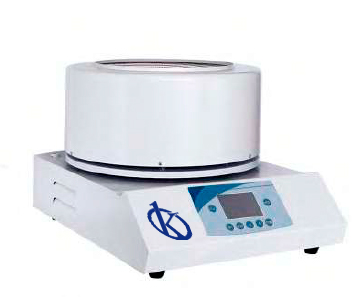

Kalstein brand laboratory incubator

We at Kalstein are manufacturers and offer a wide range of laboratory products with the best technology on the market, specially designed for all industrial chemical and pharmaceutical sectors. We have for our customers the Incubators belonging to the YR series. It has world-famous compressor: balanced cooling technology, automatic defrosting, multiple safety system, long running, environmental protection, high efficiency and energy saving. Automatic defrosting function: rapid defrosting technology by original heat pump, for continuous operation, effectively prevents frost due to continuous operation of the evaporator. They are easy to install, among other more attractive qualities that can be appreciated from our catalog HERE For any type of equipment, the cost factor is important and Kalstein has the best prices. In addition, we are manufacturers and offer you the best advice to make your purchase the ideal. We invite you to visit our website HERE