Ovens

Ovens, also known as drying stoves, are devices used to dry and sterilize glass and metal containers used in various laboratory processes. The laboratory stoves allow to carry out the sterilization by dry heat, where hot air is used to carry out this process, these equipments allow a uniform distribution of heat inside, where the material is exposed to temperatures of approximately 170ºC for 2 hours.

Dry heat sterilization works by destroying microorganisms by oxidation of their cellular components. This is a less efficient process than wet heat sterilization because microorganisms die more quickly when in the presence of water because it allows their protein configuration to be altered more easily and provides a means of evenly distributing heat throughout the sterilizing equipment’s internal chamber. For this reason, to achieve the sterilization of the material using dry heat, higher temperatures should be applied for a longer time.

Types of Ovens your Laboratory may need

With drying

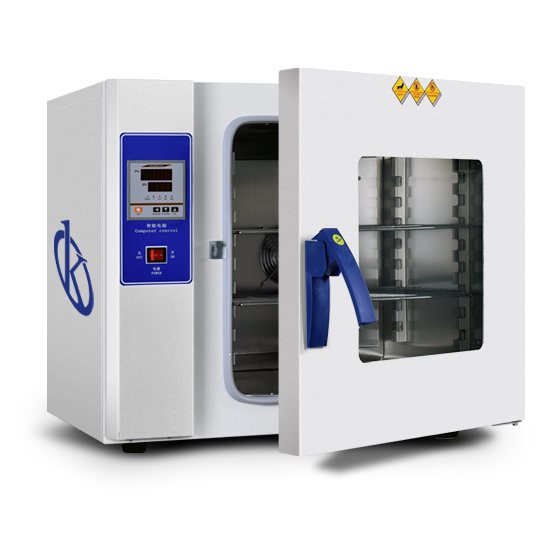

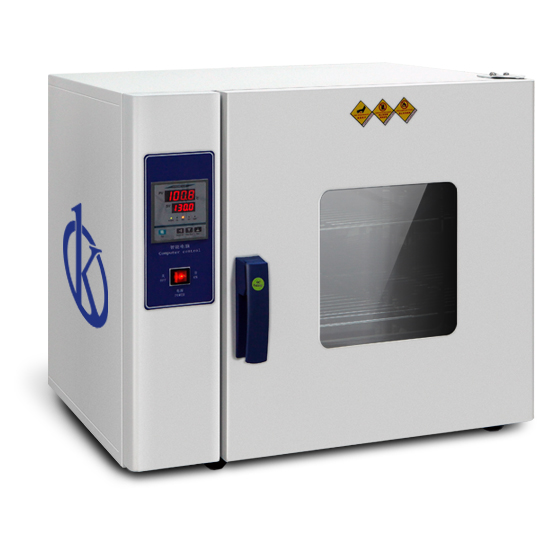

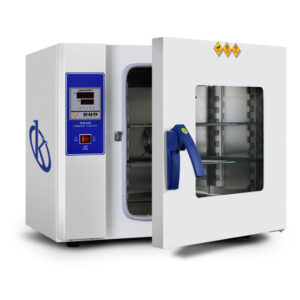

Within the category of Ovens, one subcategory to consider is “With Drying,” which focuses on laboratory ovens equipped with drying capabilities. These specialized ovens are essential for processes that require careful drying of samples or materials. With precise temperature control and airflow features, ovens in this category ensure efficient and thorough drying, making them valuable assets in laboratories across various industries.

Laboratory ovens with drying functionalities are designed to meet the specific needs of scientific and research applications. By incorporating drying capabilities into the oven design, researchers and technicians can streamline their processes and achieve consistent results. Whether it’s for drying glassware, preparing samples for analysis, or conducting delicate experiments, these ovens offer the reliability and performance required in a laboratory setting.

Into the void

When delving into the realm of laboratory equipment under the parent category of “Ovens,” exploring the subcategory of “Vacuum Ovens” opens up a whole new world of possibilities for scientific research and experimentation. Vacuum ovens, also known as drying ovens, create low-pressure environments by removing air and moisture, ideal for processes such as drying, curing, or dehydrating delicate samples without causing damage. These specialized ovens are essential in various scientific fields, including chemistry, biology, and material science, where precision and control are paramount.

The design of vacuum ovens allows for specific temperature settings and consistent heat distribution, ensuring uniform drying across all samples. With advanced features such as digital controls, programmable settings, and safety mechanisms, researchers can perform experiments with peace of mind and achieve reliable results. Additionally, vacuum ovens are versatile tools that accommodate a wide range of applications, making them indispensable assets in any modern laboratory setting.

OVENS KALSTEIN

At Kalstein you can find the ideal Ovens for your Laboratory

Electric Heating Drying Oven YR06446

Precision LCD microcomputer intelligent PID control system offers temperature control, timing, and over-temperature alarm features, along with an RS485 computer interface f...

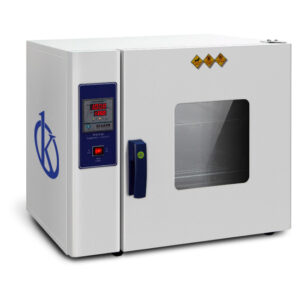

Electric heating drying oven YR05244 // YR05247

Microcomputer intelligent PID control, precision LED display temperature control, timing, over-temperature alarm, RS 485 computer interface, mirror stainless ste...

Vacuum Drying Oven YR05265-1 (SS) // YR05995 (S)

Vacuum Drying oven widely used in biochemical, chemical and pharmaceutical, health care, agricultural research, environmental protection and other resear...

Double Door Industrial Air Drying Oven YR05257-1 // YR05259-1

Double layer door; Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat fl...

Our Ovens best seller

Vacuum drying oven widely used in biochemical, chemical, pharmaceutical, health care, agricultural research, environmental protection and other research applications for powder drying and roasting,as well as disinfection and sterilization of glass containers used. Particularly suitable for drying heat-sensitive, easily decomposed, and the complex composition of easily oxidized material items for fast and efficient drying.

A variety of complex mechanical components or other porous samples after cleaning using a vacuum drying method, completely dry without leaving any residual material.

Product Introduction

Widely used in biochemical, chemical, pharmaceutical, health care, agricultural research, environmental protection and other research applications for powder Drying and roasting, as well as disinfection and sterilization of glass containers used. Particularly suitable for Drying heat-sensitive, easily decomposed, and the complex composition of easily oxidized material items for fast and efficient Drying.

| Model | YR05260 (A) | YR05262 (SS) | YR05261 (A) | YR05263 (SS) | YR05264 (A) | YR05265 (SS) |

| Supply Voltage | 220 | |||||

| Temp. Range (°C) | RT + 5 ~ 250 | |||||

| Timer Range | 0 ~ 999 min | |||||

| Material | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel | Zinc Plating Chamber | Stainless Steel |

| Temp. Accuracy | ± 1 | |||||

| Temp. Fluctuation (%) | ± 2 | |||||

| Power (KW) | 0.9 | 1.4 | ||||

| Vacuum Degree | < 133 | |||||

| Inner Size (mm) (H x W x D) | 28 x 30 x 30 | 40 x 41.5 x 35 | 44 x 48.5 x 42.5 | |||

Analysis of the best Ovens for your Laboratory

Is a ovens in a clinical laboratory important?

A ovens is an essential instrument, both in clinical and scientific research laboratories, with its use can be removed, by drying and sterilizing, moisture from met...

Importance of a drying oven in a laboratory

Currently there are many types of laboratory equipment and instruments, but one of the most common and important are drying ovens. A drying oven is an instrument used to d...

Is laboratory oven the same as a laboratory oven?

Laboratory ovens or also called laboratory ovens are equipment that is used to dry and sterilize different materials and laboratory instruments, as well as to dehydra...

Main differences between a laboratory ovens and a laboratory incubator

Among the great variety of equipment needed to carry out the many activities of a laboratory, we can highlight the use ...

Catalog of models of Ovens on offer

Single Door Industrial Air Drying Oven YR05256 // YR05258

Select options

Double Door Industrial Air Drying Oven YR05257-1 // YR05259-1

Select options

Vacuum drying oven YR05260 (A) // YR05261 (A) // YR05264 (A)

Select options

Vacuum Drying Oven YR05265-1 (SS) // YR05995 (S)

Select options

Electric heating drying oven YR05244 // YR05247

Select options

Electric heating drying oven YR05248 // YR05255

Select options

Electric Heating Drying Oven YR05259-2

Add to cart

Electric Heating Drying Oven YR06446

Add to cart

KALSTEIN UPDATED

Guidelines for you to become an expert in Ovens

The Ovens equipment are essential products in your Laboratory, we provide you with guidance and recommendations for a better use, so you can work like an expert.

Importance of the ovens for the Agri-Food Industry

How does the Vacuum ovens work in the Laboratory?

Use of Laboratory Vacuum ovens for Pharmaceutical Sector

Laboratory ovens and muffles: What are the differences and applications?

Frequently asked questions from our customers about Ovens

The delivery time of your Kalstein product will depend on the following:

- Whether the equipment you are interested in is in stock or if it needs to be manufactured.

- The type of freight you have chosen, which can be either air or sea.

- Equipment in stock:

– Delivery Time (Air): 15-30 days.

– Delivery Time (Sea): 45-60 days.

- Equipment not in stock:

– Delivery Time (Air): 30-60 days.

– Delivery Time (Sea): 60-90 days.

You can make your purchase through:

- By email: [email protected]

- By phone: +33 (0) 1 70 39 26 50

- Online shopping: Through the official Kalstein website in your country.

At Kalstein, we provide our customers with inductions and technical support through new online methods. You can visit our induction videos, technical assistance, and guidance provided by a Kalstein team through our Youtube channel (Kalstein English). HERE

Send us a direct message and one of our agents will contact you

Ovens

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed dignissim placerat mauris cursus laoreet. Nam feugiat lacus ex, at fermentum sapien accumsan nec. Curabitur auctor porttitor mi non malesuada. Aenean condimentum, purus vitae rhoncus imperdiet, justo eros aliquam ipsum, at egestas leo diam eget libero.

Catalog of models of Ovens on offer.

-

Electric Heating Drying Oven YR06446

-

Electric Heating Drying Oven YR05259-2

-

Electric heating drying oven YR05248 // YR05255

This product has multiple variants. The options may be chosen on the product page -

Electric heating drying oven YR05244 // YR05247

This product has multiple variants. The options may be chosen on the product page -

Mini Centrifuge With Large Capacity YR012G

-

Tabletop High Speed Centrifuge YR0137-2 – YR0137-3

This product has multiple variants. The options may be chosen on the product page -

Gel Card Centrifuge YR142-3 – YR142-3-1

This product has multiple variants. The options may be chosen on the product page -

Tabletop High Speed Centrifuge YR019-TG

This product has multiple variants. The options may be chosen on the product page -

Intelligent Electric Wheelchair YR06432

-

Electric Wheelchair YR05445

-

Electric Wheelchair YR05443

-

Electric Wheelchair YR05442

-

Electric Wheelchair YR05444

-

Electric Wheelchair YR05441

-

Electric Wheelchair YR05440

-

Electric Wheelchair YR05439

Descubre más de nuestro catálogo

Tipos de Ovens

[Producto] A

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

[Producto] B

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Find out more about Ovens with our guides.

TOC Analyzer: Accurate Measurement of Total Organic Carbon in Liquids

The measurement of total organic carbon (TOC) is essential in various industries such as pharmaceuticals, food, and environmental monitoring. TOC...

Veterinary Ultrasound: Fast and Non-Invasive Diagnosis for Animal Care

The use of veterinary ultrasounds has revolutionized the diagnosis and treatment of animals, enabling precise, fast, and comfortable medical examinations....

Veterinary Ultrasound: Fast and Non-Invasive Diagnosis for Animal Care

The use of veterinary ultrasounds has revolutionized the diagnosis and treatment of animals, enabling precise, fast, and comfortable medical examinations....