The balance is used to measure the mass of a body or substance or also the weight thereof; since there is a well-defined relationship between mass and weight. In the laboratory, the balance is used for quality control activities, for preparing mixtures of components in predefined proportions and for determining specific densities or weights. Its origins lie more than 3500 years before Christ, in Egypt.

Balances differ in design, principles used and metrology criteria used. At present, two major groups could be considered: mechanical scales and electronic scales.

Mechanical balances

- Spring balance: Its operation is based on a mechanical property of springs, which is that the force exerted by a spring is proportional to the constant elasticity of the spring [k] multiplied by the elongation of the spring [x] [F = -kx].

- Sliding weight balance: It has two masses; known that can be moved on scales – one with a macro graduation and the other with a micro graduation – by placing a substance of unknown mass on the tray; its weight is determined by sliding the masses on the above scales until the equilibrium position is obtained.

- Analytical balance: Works by comparing known weight masses with the mass of a substance of unknown weight. It is built on a symmetrical bar or lever that is supported by a blade-like support at a central point called a fulcrum.

- Upper plate balance: This type of balance has a loading plate placed on top, which is supported by a column that is held upright by two pairs of guides that have flexible couplings. The effect of the force, produced by the mass, is transmitted from some point of the vertical column either directly or by some mechanism to the load cell.

- Replacement balance: It is a single saucer balance. An unknown mass is placed on the weighing plate and balanced by removing masses of known magnitude from the counterweight side using a mechanical cam system until a steady position is reached.

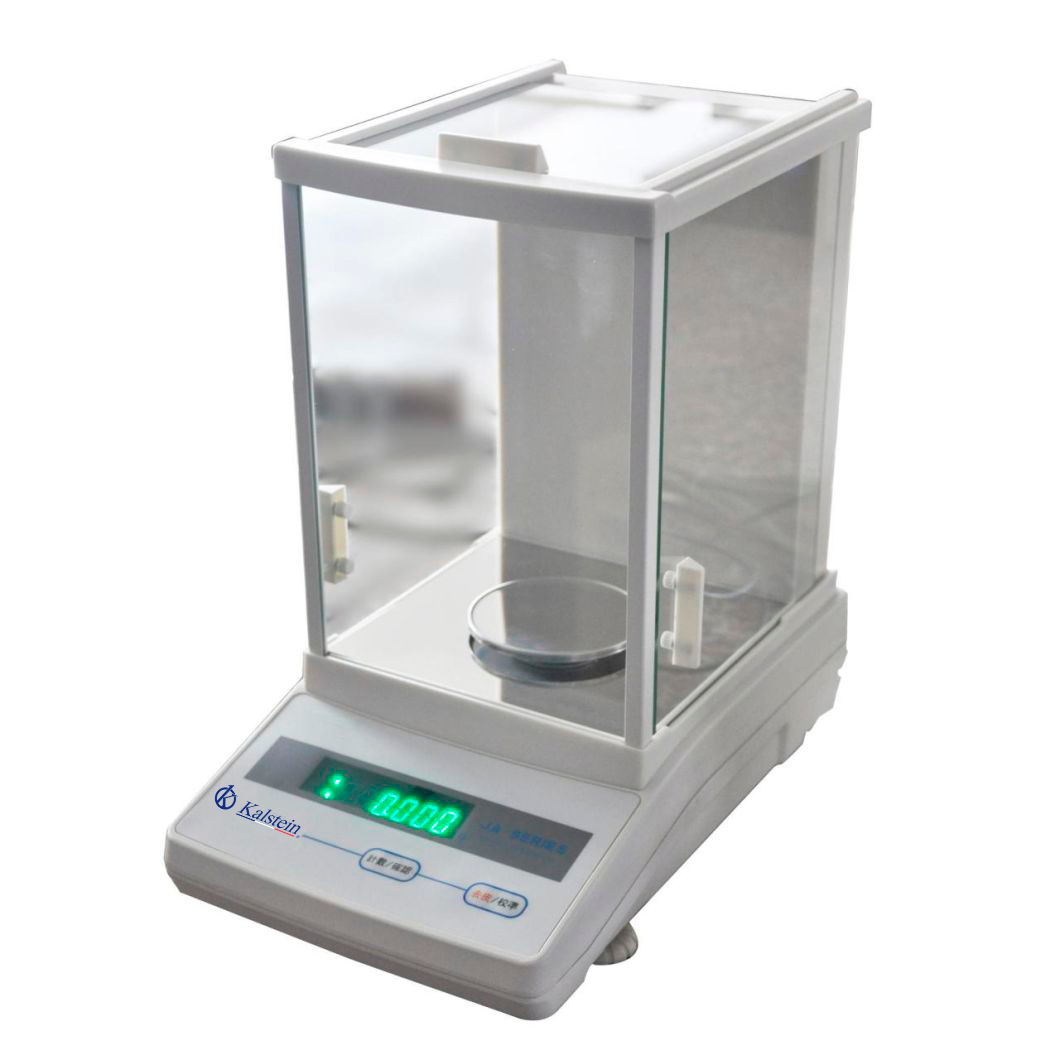

Electronic balances

- The object to be weighed which is placed on the weighing pan exerts a pressure which is randomly distributed over the surface of the weighing pan.

- A measuring transducer, known as a load cell, produces an output signal proportional to the load force, in the form of changes in voltage or frequency.

- A digital analog electronic circuit that finally presents the weighing result in digital form.

What is required to successfully install and operate a Balance?

- Have an environment that does not present air currents, sudden changes in temperature and that is free of dust.

- Have a perfectly level inn. A high-inertia platform, insulated from neighboring structures, is ideal for reducing the effect of vibrations emitted by certain equipment such as centrifuges and refrigerators. It must have a sufficient area to install the balance and the auxiliary equipment with which it interacts in the weighing processes. The space required by the interconnecting cables, electrical current, connection to the information system, to the printer, etc. should also be provided.

- Avoid the installation in the vicinity of equipment producing high magnetic fields or vibrations such as centrifuges, electric motors, compressors and generators.

- Avoid being under the direct influence of air conditioning systems – drafts – and sunlight.

- Have an electrical outlet in good condition, equipped with ground pole provided with switches, that meets the electrical regulations in force in the country or the laboratory.

At Kalstein we present sophisticated electronic scales, equipment with a high level of technology and precision that will allow you to obtain in your laboratory much more reliable results. That’s why we invite you to take a look HERE